Registered users can place Bulk Orders . Contact local Coats office for registration.

Learn more about the innovations we’re making in the fascinating field of composite materials, creating new products that withstand nature’s wildest forces by taking inspiration from the natural world.

Create advanced, high-performance thermoplastic products that are lightweight yet extremely strong.

A polypropylene copolymer extruded tape reinforced with high modulus aramid cords.

Gotex XTRU PE A is an innovative tape that strengthens and preserves the life of flexible pipes used in oil and gas.

A revolutionary fibre-laying technology that uses eco-friendly raw materials.

Coats Lattice and Lattice Lite technology perfectly complements our range of Synergex composite fibres by maximising performance and eliminating waste.

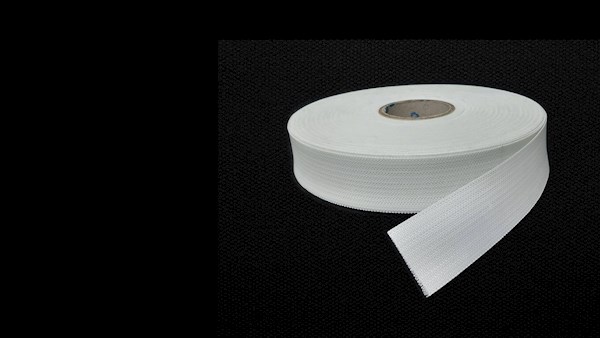

A fibreglass woven tape used in telecommunications cables to prevent damage from rodents.

A new generation of high performance Gotex fibre that can be used as a strength element in fibre optic cables.

Coats Ultrabloc SY is a water-swellable polymer yarn that can resist salt and sea water, and withstand extreme temperatures.

A sustainable, continuous filament yarn designed specifically for ripping applications.

Advanced composites require advanced design. We have created a unique set of 3D modeling tools that let you customise your product by selecting the composites that meet your specific demands.

With our global expertise, innovative solutions and technical support, Coats can help you meet your automotive needs now and in the future.

Read more

We have created a 3D tool for product selection from a range of knitting yarns, composites and threads to create the base for a sports shoe.

Read more

View our new product selector tool to learn more about our innovative products for the telecom industry.

Read more

See how our approach is benefitting customers across the globe in composite material innovation.