Sustainability Certifications

Overview

Sustainability is at the very heart of our strategy at Coats. It encompasses the products we create and sell through innovation, as well as how we manage our operations. Our investment in sustainability, and leadership in sustainable innovation provides a strong competitive advantage with our customers.

The raw materials that we convert into finished goods contain more than 65% of our total value chain emissions and delivery of both our interim 2030 Scope 3 Science Based emissions reduction target and our 2050 Net Zero targets are contingent on us transitioning to materials with lower embedded emissions.

Managing precious resources wisely

Renewables for sustainable future

Protecting our planet

Footwear: Market leader shaping the future of footwear thread and components

Performance Materials: Transforming the footprint for growth

Zero Discharge of Hazardous Chemicals

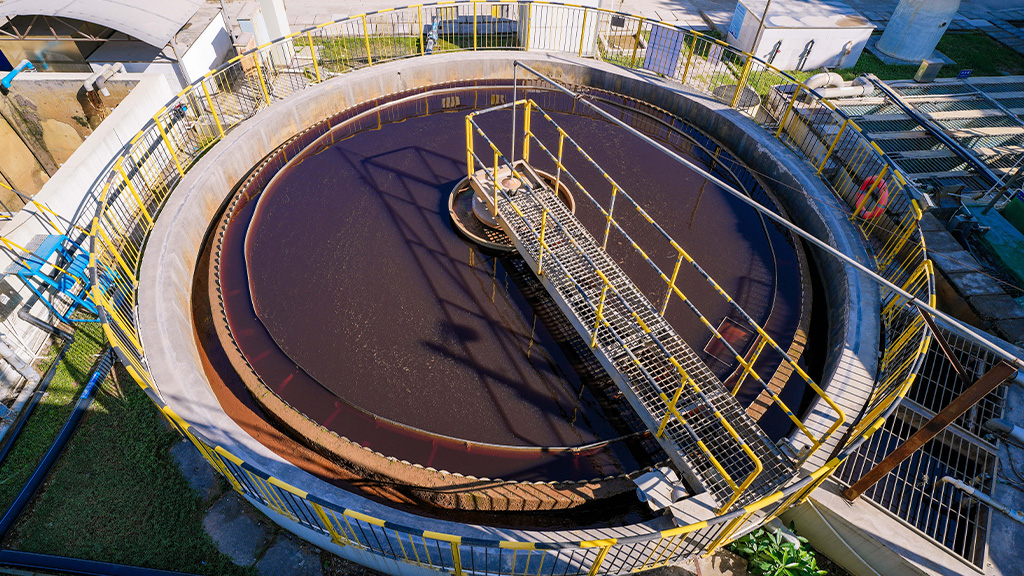

At Coats, we continued to deliver on our Effluent Compliance commitments which are focussed on eliminating hazardous chemicals from our supply chain.

OEKO-TEX®

OEKO-TEX® standards enable everyone to make responsible decisions and protect natural resources.

- Coats India — 08-6898 | 11-50576 | 11-61192 | 11-69584 | 14038

- Coats India — 11-40291 | 11-61332 | 11-63158 | 11-39642

- Coats Indonesia — 11-36904 | 11-61548

- Coats Bulgaria — 11-33876

- Coats Bangladesh — 11-34931 | 11-63636 | 11-34526 | 11-63304

- Coats Group plc — 11-36001 | 11-37257 | 11-64846

- Coats Colombia — 11-39561 | 11-62848

- Coats Egypt — 11-21535 | 11-61091

- Coats Vietnam — 11-32686 | 11-62347 | 11-24395 | 11-24396 | 11-62362

- Coats Honduras — 11-67844 | 11-37710

- Coats Pakistan — 11-63584 | 11-63889 | 08-7187

- Coats Morocco — 11-72274 | 11-38031

- Coats Mexico — 11-36192 | 11-40094

- Coats China — 11-60314 | 18046 | 11-36117 | 11-60660 | 11-68351

- Coats China — 11-36896 | 11-61051 | 11-60254 | 11-36212

- Coats Thailand — 11-61506 | 11-39397

- Coats Sri Lanka — 11-64538 | 08-4377

- Coats Romania — 11-62943 | 11-37362

- Coats Turkey — 11-32734 | 11-62310 | 17092 | 11-46326

- Coats Tunisia — 11-67885 | 11-40258

Restricted Substances List

We believe our Coats Restricted Substance Lists (both our Products RSL and our Manufacturing RSL) are the most stringent in the textile industry.

Product safety

Coats MRSL

Better Cotton™

Better Cotton is the world’s leading sustainability initiative for cotton.

Global Recycle Standard

The Global Recycled Standard (GRS) is a voluntary product standard for tracking and verifying the content of recycled materials in a final product.

Coats ensures that any facility that processed recycled materials is externally certified to GRS and that any recycled materials that we buy are certified so that we can provide fully certified recycled products.

Global Organic Textile Standard

The Global Organic Textile Standard (GOTS) is an internationally recognized certification for organic textiles.

Higg Index

The Higg Index is a suite of tools developed by the Sustainable Apparel Coalition (SAC) to measure and improve the environmental and social sustainability of apparel, footwear, and textile products across the entire value chain.

- Coats Bangladesh - Chittagong: 124937

- Coats Bangladesh - Dhaka: 140852

- Coats Bulgaria : 145803

- Coats China - Qingdao: 125472

- Coats China - Shanghai: 123706

- Coats China - Shenzhen: 33114

- Coats China - Tianjin (JYSC): 137565

- Coats China - Rx Dongguan: 140210

- Coats China - Tx Dongguan: 124528

- Coats Colombia - Pereira: 145906

- Coats Egypt: 50214

- Coats Honduras: 125574

- Coats India - Ambasamudram: 131332

- Coats Indonesia: 17752

- Coats Mexico - Orizaba: 125546

- Coats Morocco: 146097

- Coats Pakistan - Karachi: 145676

- Coats Pakistan - Lahore: 145675

- Coats Romania: 145933

- Coats Germany - Rx Ludwigshafen: 17746

- Coats Germany - Tx Möckmühl: 130121

- Coats Vietnam - Rx: 148039

- Coats Vietnam - Tx: 164242

- Coats Vietnam - Hanoi: 145723

- Coats Vietnam - Ho Chi Minh City: 122647

- Coats Sri Lanka: 130564

- Coats Thailand: 138105

- Coats Tunisia: 145970

- Coats Turkey: 123076

- Coats Italy - Tx Montemurlo: 168706

- Coats Italy - Tx Ripatransone: 130252

- Coats Group plc - Tx Skelton: 122523

Great Place To Work®

Great Place To Work® (GPTW) is an organisation which allows companies to quantify their culture and produce better business results by creating a high-trust work experience for all employees. Coats is partnering with GPTW since 2021.

In the next phase of our sustainability journey, we will continue to utilise Great Place To Work® (GPTW) as the primary barometer to measure levels of employee engagement and trust, and are committed to further enhancing our current percentage of employees covered with certification to 88% in 2026 and aspirations to achieve 90% by 2030.

Coats India has once again been recognised among the Top 25 India’s Best Workplaces™ in Manufacturing 2026 – Large Category by Great Place To Work® India.

Great Place To Work® invites applications from Manufacturing organisations to be assessed and evaluated for being considered among India’s Best Workplaces™ in Manufacturing. 361 organisations in the Manufacturing sector underwent a rigorous assessment with the aim of achieving this prestigious certification. Being ranked among the Top 25 in the Large category is a significant achievement and a testament to the strong culture we continue to build together at Coats.

Earning this recognition again reflects our unwavering commitment to fostering trust, pride, collaboration, and inclusivity across the organisation. It reinforces that our focus on employee wellbeing, equitable opportunities, strong leadership, and continuous innovation is making a meaningful difference.

Recognitions awarded by Great Place To Work®

|  |