Productivity

that increase your productivity and speed to

market.

Reduce repairs, avoid thread breakages and gain productivity with our high

quality sewing threads and zips for denim pieces.

- Superior sewing performance and increased productivity on your denim

sewing lines - Reduced thread damage and thread breakages during industrial wash

processes

Contents

Hidden cost of thread

How much is denim washing costing you?

Use the Coats denim calculator to improve your denim productivity

Tap into our expertise to solve your denim problems

Hidden cost of thread

Although thread is not an expensive component, it has a significant impact on output

and sewing productivity. The wrong choice of thread hampers production and can result in

problems such as thread breakage, sewing stoppages, slower machine speeds, and higher

repair rates after denim wash programmes.

The hidden cost of choosing the wrong thread

- Thread breakage

- Skipped stitches

- Sewing stoppages

- Needle breakage

- Slower machine speeds

- Higher repair rates

- Poorer quality garments

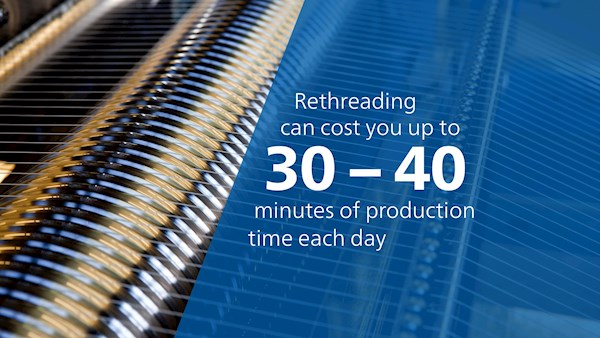

When a thread breaks, rethreading takes 7 seconds in a lockstitch machine, and up to 2 minutes in an overlock or cover seam machine. These interruptions in the production line could cost you 30 to 45 minutes of productive time each day.

When choosing the right thread for denim production, qualities including their impact on machine performance, seam strength and durability are crucial. Corespun threads, like Coats Epic and Dual Duty, have been developed for modern day factories. Due to their construction and specially formulated lubrication, these high tenacity and versatile threads are ideal for denim production. They deliver excellent sewing performance in the most demanding applications such as automatic pocket setting, and provide outstanding abrasion resistance.

Key considerations when selecting sewing threads for denim production

- Impact on machine speed and performance

- Seam strength to keep the seam secure

- Seam stretch to provide the elongation required

- Durability and toughness to withstand the washdown processes

- Qualities to create the desired appearance, including colour fastness or fade, and thickness for stich definition

Take advantage of the benefits that Coats sewing threads can bring to your denim production process – fewer repairs and higher optimum running speeds.

How much is denim washing costing you?

Are you washing your dollars down the drain? Using the wrong thread can result in post-

washing repair rates as high as 40%. With Coats’ proven denim solutions you can banish

costly after wash repairs and focus on creating high performance iconic denim pieces

which will last a lifetime.

Denim washing processes are many and varied. Often the objective is to distress the

garment to achieve a desired appearance and to soften an otherwise harsh fabric.

However, denim washing can have a devastating effect on sewing threads and therefore

seams if care is not taken in their selection and application.

Coats’ range of sewing threads have been designed specifically to withstand the rigours of

denim washing and to create distinctive denim pieces through contrast colours and other

decorative applications.

Common denim washing challenges

Include:

- Undesired colour changing after bleach washes

- Seam weakening and broken stitches after pumice stone washing

- Seam abrasion and poor seam appearance after enzyme washing

The benefits of using Coats’ sewing threads to withstand denim washing

Include:

- Colour fastness

- Unique faded effects and washdown characteristics

- Protection against thread breakages and seam abrasion

- Excellent seam appearance after washing

With our tried and tested denim solutions and expert technical advisory team, Coats can support you in selecting the optimal threads and denim wash process to meet your unique denim needs.

Use the Coats denim calculator to improve

your denim productivity

your denim productivity

Use the Coats denim calculator to calculate the savings you can incur by using Coats

corespun threads for denim sewing. Using data from productivity and wash studies and

your own data for reduced repair rates, the Coats denim calculator can save you a small

fortune. We’ll support you to make your denim washing process durable, reliable, fast and

cost effective.

Tap into our expertise to solve your denim

problems

problems

Our unique tools and expert technical support can help you optimise your processes at

every stage of the denim process, from design to sourcing, manufacturing and

consumption.

We can work with you to address your denim problems, from reducing thread breakages in

stretch denim fabrics to preventing the melting of polyester threads during the laser

process. Our technical advisory experts are at hand wherever you are located in the world.

Coats can work with you to address a whole range of denim problems

Include:

- looper thread breakages in chain stitching after washing

- thread breakages after scraping

- melting of polyester threads during the laser process

How it works

Our technical experts will review your operations to:

- identify which styles and processes have issues

- carry out thread audits on each of your sewing operations

- provide thread recommendations to reduce your repair rates and offer advice at the needle point

- monitor these corrective actions and establish their effectiveness

- provide a financial summary of savings incurred