Semua Tentang Jarum

Daftar Isi

Fungsi dasar Jarum

Bagian-Bagian Jarum: Ciri-ciri Fisik

Identifikasi Jarum

Jarum Ujung Bundar

Ukuran / Ketebalan Jarum

Perbandingan Jarum dengan Ukuran Sama

Masalah-Masalah Umum dan Solusinya

Daftar Periksa Jarum

Memeriksa Jarum yang sudah terpasang pada Mesin

Pendahuluan

The central feature of any sewing machine is the needle or needles. Very many needle types (Sistems) have been developed over time to ensure each sewing machine that uses them performs at its best.

Needle Sistems may be introduced for a number of Penyebabs such as the Pendahuluan of new or specialised fabrics, new sewing machinery or even increases in machine speed.

Each needle Sistem (needle type) will typically have between 6-8 Ukurans available, and in the more popular Sistems there can be up to 15 Ukurans, with each of these needles Sistems and Ukurans being available in a range of different needle Ujung jarums.

Panduan berikut ini dimaksudkan untuk memberi pengetahuan yang lebih baik mengenai jarum mesin jahit.

Fungsi dasar Jarum

- To create a passage in the material for the thread to pass through.

- To carry the needle thread through the material and form a loop which can be picked up by the hook or looper mechanism.

- To pass the needle thread through the loop formed by the looper mechanism on machines other than lockstitch.

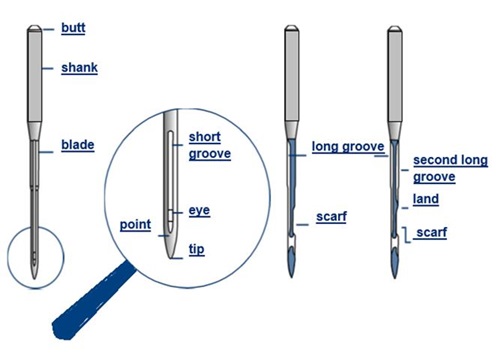

Bagian-Bagian Jarum: Ciri-ciri Fisik

Jarum memiliki berbagai bagian dengan fungsi-fungsi yang berbeda pada saat proses menjahit seperti yang tercantum berikut ini:

- Bagian Pangkal – Bagian pangkal yang berfungsi sebagai tempat untuk memasukkan jarum ke rumah jarum / penjepit jarum

- Bagian Atas – Bagian jarum yang lebih tebal yang dijepit oleh penjepit jarum atau sekrup jarum. Bagian ini menopang seluruh bagian jarum sebagai kekuatan tambahan

- Bahu – The intermediate section between the Bagian Atas and the Bagian Runcing Jarum

- Bagian Runcing Jarum – The needle portion extends from the Bagian Atas to the Mata jarum. This is subjected to the greatest amount of friction and hence heat when it passes through the material

- Alur jarum yang panjang(s) – It is present in one side of the needle Bagian Runcing Jarum for the convenience of the needle thread from the take-up device and provides a protective channel in which the thread is drawn down through the material during stitch formation

- Alur jarum yang pendek – Bagian ini berada pada sisi lain dari alur jarum yang panjang, menghadap ke shuttle, pengait, atau looper dan membantu proses pembentukan simpul pada benang

- Mata jarum – The Mata jarum of the needle is present in the bottom end of the Bagian Runcing Jarum. Needle thread allowed through this Mata jarum is taken to the bottom area

- Bagian cekung (Clearance) – It is a clearance cut in the needle Bagian Runcing Jarum just above the Mata jarum to permit a closer setting of the shuttle, hook, or looper to the needle

- Ujung jarum – The Ujung jarum of the needle is shaped to provide the most suitable penetration of the material being sewn according to its nature and the desired stitch effect

- Titik Ujung Jarum – The extreme Titik Ujung Jarum shape, in combination with the Ujung jarum defines penetration performance

- Bagian-bagian lain – Kebanyakan jarum dibuat dengan berbagai bagian ini namun juga terdapat sejumlah pengecualian. Beberapa jarum dibuat untuk proses penjahitan tertentu atau memang dirancang khusus untuk mesin jahit tertentu

Identifikasi Jarum

Sebuah jarum mesin jahit diidentifikasikan dengan tiga parameter berikut ini:

- Sistem

- Ujung jarum

- Ukuran

Sistem

A needle Sistem defines the dimensions of a needle to suit the machine type. Depending on the machine and its stitch type, the needle is designed with variations in length of Bagian Runcing Jarum, Bagian Atas thickness, type of Mata jarum etc. It is advisable to check with the machine manufacturer for suitability of needle Sistem to machine.

Ujung jarum

A needle Ujung jarum is classified broadly into two types:

- Round, set or cloth Ujung jarums

- Cutting or leather Ujung jarums

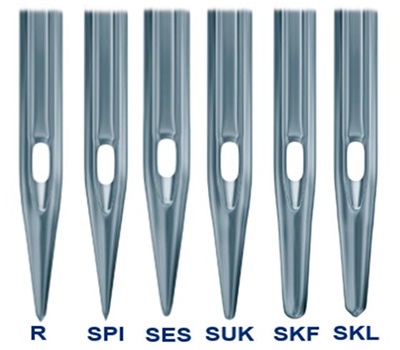

Jarum Ujung Bundar

There are believed to be around twenty different round Ujung jarums available out of these six are in common use.

Jarum Ujung Bundar - Applications:

- Slim Set Ujung jarum also referred to as acute round Ujung jarum (SPI)

This Ujung jarum is used for dense woven fabrics as it causes less damage, helps set a straighter stitch and minimizes seam pucker.

Biasa digunakan pada microfibre dan kain tenun yang padat, kain-kain dengan lapisan khusus, setikan tindas atas pada kerah dan ujung lengan pada kemeja. - Set Cloth Ujung jarum also referred to as normal round Ujung jarum (R)

This Ujung jarum is used for normal fabrics with standard seams as it pushes the yarn to the side. - Light Ball Ujung jarum (SES)

This Ujung jarum is used for sewing lightweight knitted fabric. It is sometimes used for fine denim and light, densely woven material to avoid damaging the material. - Medium Ball Ujung jarum (SUK)

This Ujung jarum is used for sewing medium weight knitted fabric. It is also used for medium to coarse denims, particularly sand-washed and stonewashed grades. - Heavy Ball Ujung jarum (SKF)

This Ujung jarum is used for coarse knitwear and for sewing dense woven elastic (it won’t push the elastic yarn through). - Special ball Ujung jarum (SKL)

Digunakan untuk bahan kain elastis yang medium hingga kasar dengan benang berlapis elastomerik dan pakaian rajut yang sangat kasar.

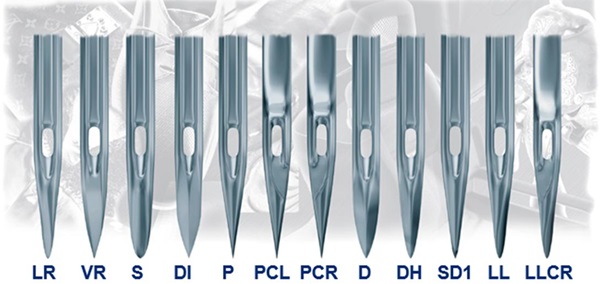

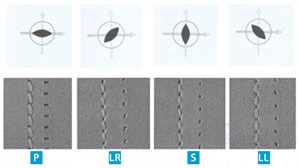

Cutting Ujung jarum Needles

Cutting Ujung jarum needles have sharp Titik Ujung Jarums like Bagian Runcing Jarums. These Titik Ujung Jarums are available with a wide variety of cross-sectional shapes such as lens, rounded, triangular and square. They can be used while sewing dense, non-fabric based material. They pierce the material more readily than the round Ujung jarum types thereby generating less needle heat. There are a large number of cutting Ujung jarums of which around 11 are in regular use.

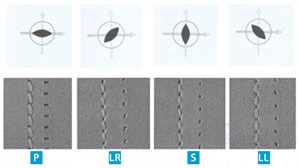

Cutting Ujung jarums Overview

Cutting Ujung jarums spear

Cutting Ujung jarum wedges

Ukuran / Ketebalan Jarum

The Ukuran of a needle is generally represented in one of two ways (although there are others). One method is by a number metric (Nm). This represents the diameter of the needle Bagian Runcing Jarum in hundredths of a millimetre measured just above the Bagian cekung but not at any reinforced part of the Bagian Runcing Jarum. For example, a Nm 110 needle is 1.1 millimetre in diameter, while a Nm 50 needle is half a millimetre in diameter.

The thickness of the Bagian Runcing Jarum below is 1.1mm wide which is shown in Nm as 110.

The alternative standard needle sizing method is the Singer/Asia numbering Sistem sometimes referred to as the American Sistem that uses a number that represents a Ukuran.

Below shows these Nm and Singer comparisons along with a number of other Ukuran references.

Perbandingan Jarum dengan Ukuran Sama

| Singer | Metric (Nm) | Union Special | Lewis | Merrow | W&G New No. | 459R | 292 Bonis |

|---|---|---|---|---|---|---|---|

| 3 | 35 | - | - | - | - | 22 | - |

| 4 | 40 | - | - | - | - | 21 | 22 |

| 5 | 45 | - | - | - | - | 20 | 21 |

| 6 | 50 | - | - | - | - | 19 | 20 |

| 7 | 55 | 22 | - | 0 | 22 | 18 | 18 |

| 8 | 60 | - | 2 | 0 | 24 | 17 | 16 |

| 9 | 65 | 25 | - | 0 | 25 | 16 | 14 |

| 10 | 70 | 27 | 2.5 | 1 | 27 | 15 | 13 |

| 11 | 75 | 029/030 | - | - | 30 | 14 | 12 |

| 12 | 80 | 32 | 3 | 2 | 32 | 13 | 11 |

| 13 | 85 | 34 | - | - | - | - | 10 |

| 14 | 90 | 36 | 3.5 | 3 | 36 | 12 | 9 |

| 15 | 95 | 38 | - | - | - | - | - |

| 16 | 100 | 40 | 4 | 4 | 40 | 11 | 7 |

| 17 | 105 | 42 | - | - | - | - | - |

| 18 | 110 | 44 | 4.5 | 5 | 44 | 10 | 6 |

| 19 | 120 | 047/048 | 5 | 6 | 48 | 9 | 4 |

| 20 | 125 | 49 | - | - | 49 | - | - |

| 21 | 130 | - | - | 7 | 52 | 8 | 3 |

| 22 | 140 | 54 | 5.5 | - | - | 7 | 2 |

| 22.5 | 150 | 60 | 6 | 8 | - | 6 | 1 |

| 23 | 160 | - | - | - | - | - | 0 |

| 23.5 | 170 | 67 | - | 9 | - | - | - |

| 24 | 180 | 78 | 7 | - | - | - | - |

| 25 | 200 | 079/080 | - | 10 | - | - | - |

| 26 | 230 | 90 | - | - | - | - | - |

| 27 | 250 | 100 | - | - | - | - | - |

| 28 | 280 | 110 | - | - | - | - | - |

| 29 | 300 | 120 | - | - | - | - | - |

| 30 | 330 | - | - | - | - | - | - |

| 31 | 350 | 140 | - | - | - | - | - |

| 32 | 380 | - | - | - | - | - | - |

| 32.5 | 400 | 156 | - | - | - | - | - |

Menentukan jarum yang tepat untuk kain

Here’s a quick way to determine if the thread and the sewing machine needle are compatible:

- Take half a metre of the thread being used on the machine and thread it through the Mata jarum of a loose needle.

- Hold the thread vertically with the needle at the top.

- Jika jarumnya terlalu besar, jarum akan jatuh ke bagian bawah benang

- Jika jarumnya terlalu kecil, jarum akan tetap berada di bagian atas benang

- If the needle is the right Ukuran, it will slowly spiral to the bottom of the thread

Terlepas dari cara di atas, jarum yang berukuran lebih besar daripada ukuran normal harus digunakan agar dapat menusuk kain yang lebih tebal atau untuk menjahit tindas jahitan yang menonjol atau tebal.

Masalah-Masalah Umum dan Solusinya

| Penyebab | Solusi |

|---|---|

| Penggunaan jarum berkualitas buruk | Gunakan jarum bermerek yang berkualitas baik |

| Tarik kain pada saat menjahit | This puts stress on the needle and bends it out of place; so, care should be taken to ensure the cloth isn’t pulled |

| The needle doesn’t go in properly | Periksa cara pasang jarum Anda dan pastikan bahwa jarum telah dipasang dengan benar pada mesin |

| Jarumnya terlalu halus untuk jenis kain tersebut | Gunakan jarum berukuran tebal untuk menjahit kain yang lebih berat seperti denim |

| Sepatu jahit longgar | Hal ini akan menyebabkan jarum menabrak sepatu jahit dan menjadi bengkok. Gunakan obeng untuk mengencangkan sepatu jahit |

Jarum mesin jahit bisa patah pada saat proses menjahit dan beberapa penyebab patah tersebut ada di bawah ini, beserta solusinya:

Daftar Periksa Jarum

Memasang jarum baru

- Always ensure the needle is the correct needle Sistem for the sewing machine

- Make sure the needle Ukuran / Mata jarum fits the thread Ukuran being used

- Pastikan bahwa jarum terpasang pada rumah jarum dengan kencang

- Pastikan bahwa sudut jarumnya benar

- Sesudah memasang jarum ke mesin, putar roda tangan mesin secara manual untuk memastikan bahwa jarum tidak mengenai bagian-bagian lain

Memeriksa Jarum yang sudah terpasang pada Mesin

- Apakah jarum telah dipasang dengan benar??

- Apakah jarum mengenai bagian-bagian mesin lainnya??

- Apakah jarum bengkok??

- Is the Mata jarum rough or blocked with melted fibre?

- Is the Ujung jarum damaged?

- Jika ragu segera ganti jarum!