Contents

Basics of Elongation

Elongation in the Sewn Product

In apparel manufacture, thread elongation is an important factor that plays a major role in two aspects.

In sewing, elongation is critical in loop formation. Threads with lower elongation form bigger loops, and they are more safely picked up in stitch formation.

Whilst in the sewn product, elongation affects seam stretch, which affects the seam performance in the finished product.

What is elongation?

The term elongation refers to the amount that a thread stretches before it breaks, or reaches its breaking point.

How does elongation differ from elasticity?

Elasticity refers to the ability of the thread to stretch and recover to its original length following the removal of any load-causing tension that caused the thread to stretch.

Elongation at Break

Sewability of thread is a term used in reference to a sewing thread’s performance, which depends on many factors like lubrication, thermal resistance and regularity which must be considered during thread selection.

However, percentage elongation at break is one of the factors which plays an important role in thread selection as it affects sewability.

If a thread measuring 100 cm can be stretched to 110 cm, at which point it breaks, it is said to have 10 per cent elongation at break. Elongation at break is expressed as a percentage of its original length.

Percentage Elongation at Break of Some Common Substrates

Production methods and materials utilised for sewing threads vary widely, and one may come across threads which differ considerably in the amount that they can be stretched. This leads thread manufacturers to claim their different products to be superior or inferior, which is why it is essential to know the comparative elongation percentages of different threads.

Different sewing operations may require thread with different elongation properties. Hence, one must select a thread with a desired amount of elongation, depending on the sewing application.

The table given below lists the range of elongation percentages for different thread substrates.

| Substrate | Elongation (%) at Break (min-max) |

| Staple Spun Cotton | 5 – 9 |

| Staple Spun Polyester | 12 – 22 |

| Poly-poly Corespun | 13 – 24 |

| Continuous Filament Nylon | 16 – 17 |

| Continuous Filament Polyester | 17 – 18 |

| Viscose Rayon | 18 – 19 |

| Texturised Polyester | 24 – 31 |

| Polybutylene Terepthalate | 40 – 50 |

Note: The above table is indicative of elongation ranges and is meant for relative comparison purposes. From the table, one can infer that staple spun cotton thread stretches approximately 5 to 9% before it breaks.

Polybutylene Terepthalate, on the other hand, stretches approximately 40 to 50% before it breaks.

Effects of Elongation While Sewing

Elongation of a thread differs at different sewing tensions. As more and more tension is applied to the thread, the thread will stretch more, affecting loop formation. If it stretches less at certain sewing tensions, loop formation will be bigger, and the thread will be picked up more safely during stitch formation. If it stretches more, it will be difficult to catch, and consequently, improper stitch formation may occur.

Comparing elongation of different threads

Evaluating thread elongation at different sewing tensions will give a better idea of how a thread will perform during sewing operations.

In Coats laboratories, three staple spun polyester threads — A, B and C; prepared by different methods and having similar strengths — were subjected to a different loads during high speed sewing. Their elongations at these tensions were measured till the elongation at break.

It was observed that the threads had similar strengths, but different elongations at break – A =15%, B =17% and C = 21%. These measurements are shown in Figure 1. It can also be observed from the Figure that at a load of 500 grams force, threads B and C had similar elongations, while thread A had significantly less elongation.

From these measurements, it can be said that maximum tensions developed in medium grist threads rarely exceed an applied load of 500 grams force in the course of normal sewing. The elongation of a thread up to this load can affect its sewing performance, as it affects the loop forming properties of the thread during sewing. This can cause the thread to suffer from ‘skipped stitching’.

Comparing loop sizes of different threads

Using video/stroboscopic techniques, the sewing loops of threads A, B and C were studied and their relative loop sizes were compared.

Figure 2 shows a graphic representation of the loop sizes. The loop sizes of B and C are markedly smaller than that of A.

So, when threads B and C are being sewn on a production machine their smaller loop will give them a higher potential to skip stitches during:

1. Needle deflection

2. Machine offset in the loop pick-up region

Generally, during repeated tension imposed on a thread on its passage from the tension disc to a needle, some stretch is permanently lost. Threads of the same type – but from different suppliers – lose different amounts of stretch.

By measuring a thread’s elongation properties at low loads, it is possible to predict to a certain extent its vulnerability to skip stitches. Sewing threads with good elongation properties are generally manufactured based on a study of the elongation curves at sewing tensions and the sewing loop sizes. They are engineered to produce the best possible loop formations during sewing.

Thread Elongation at Break in Seam Performance

Selection of a thread based on its elongation properties plays a major role in achieving seam stretch, which is the prime indicator of a quality finished product.

Seam performance depends on seam stretch. If the percentage elongation at break of a thread is less, the amount the seam can stretch before it breaks will also be less. This, in turn, affects seam performance. Hence, it is better to have a thread with optimal elongation properties to obtain good seam performance. Optimal elongation should not be too high, or too low. Elongation should be balanced or controlled as needed, and specific needs can be met by threads with different construction and manufacturing techniques.

Note:

Along with thread elongation, other factors that can support seam elasticity are correct determination of stitch density, stitch type and seam type.

Generally, the higher the thread elongation, the better is the seam elongation, and in turn, the seam performance.

For high-stretch applications, Coats recommends:

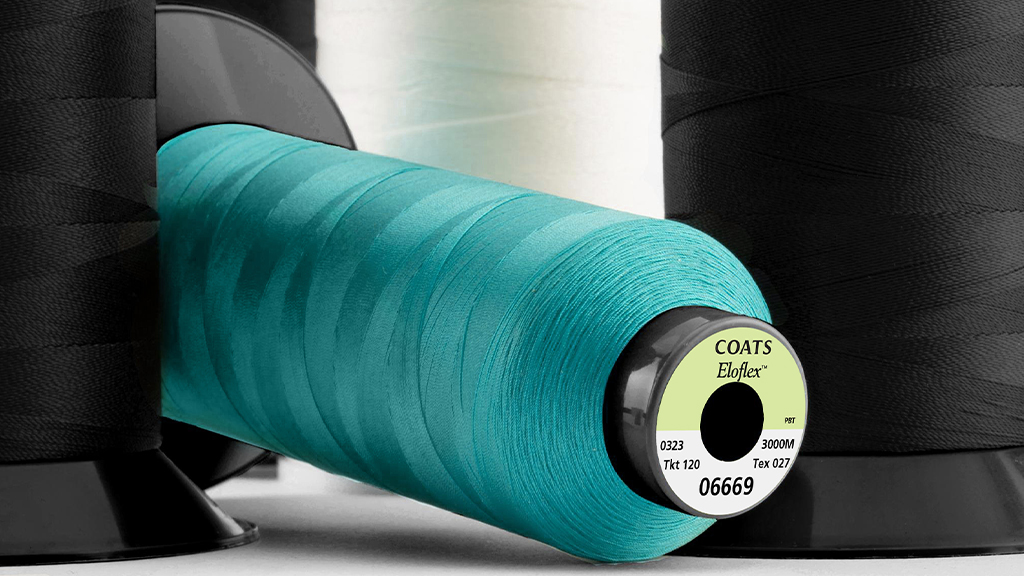

Coats Eloflex has high elasticity and good tenacity properties. With an elongation percentage at break ranging from 40 – 50%, it has high initial modulus which aids good loop formation properties, offers good sewing performance and reduces the risk of seam extension failure. Facilitating the production of high-stretch seams with good strength and durability, it is the ideal choice for seams on garments made from fabrics with high extension properties.