Coats Armoren

Game-changing solutions for hand safety

Coats Armoren uses a pioneering J Spun engineered yarn technology that extends the frontiers of safety awareness in cut protection. New generation stretch fibres and high quality of core yarn coverage creates laser-fine gloves that are comfortable, and have ultimate tactile dexterity. The best in class, proprietary helical J Spun core construction provides the power of extreme cut resistance even at fine knitting gauges.

The Coats Armoren product range of cut protect yarns is engineered for Ultralight comfort and Ultracut protection in gloves, and offers game-changing solutions to the hand safety industry.

Coats Armoren can also be designed to protect against multi-risk hazards like electric arc flash, extreme contact heat, microbial infection, molten splash, chemical exposure, clean room electrostatic, and other dangers. It is brought to you by Coats, which is a global company with the engineering expertise and the innovation capability to meet increasingly stringent industry trends of safety and sustainability.

What innovative solutions does Coats Armoren offer for safety gloves?

Click on each of the icons above to find out more.

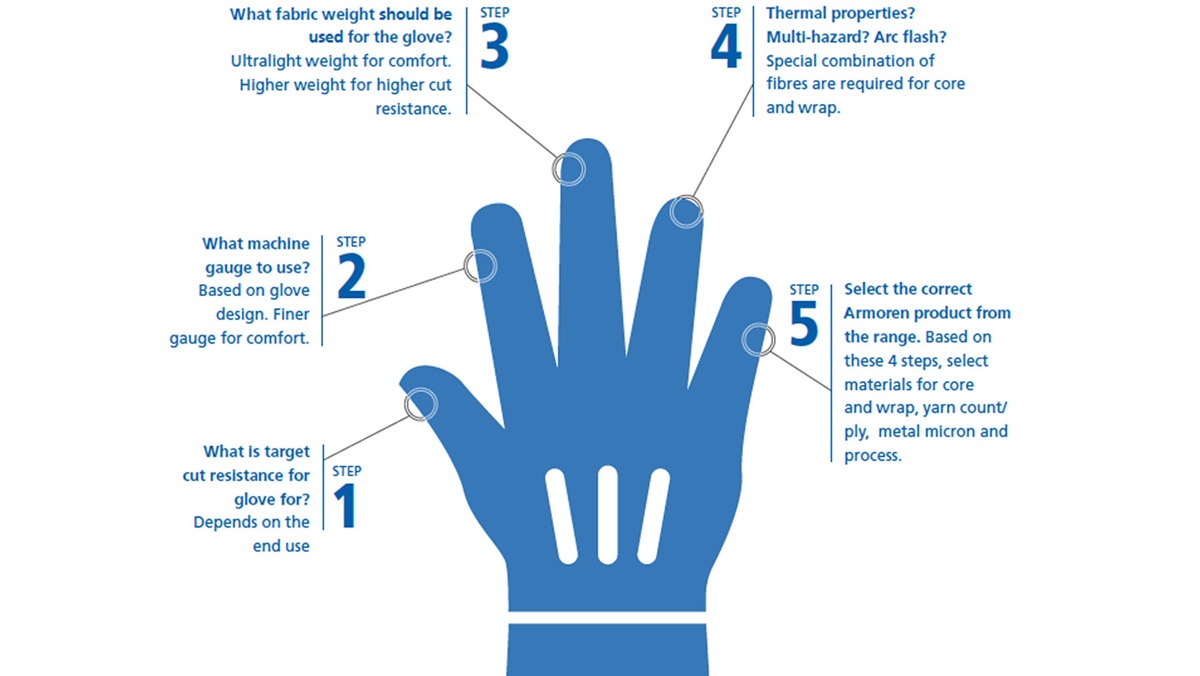

Selecting the appropriate Armoren yarn

5 steps to select the appropriate Armoren yarn for your safety product:

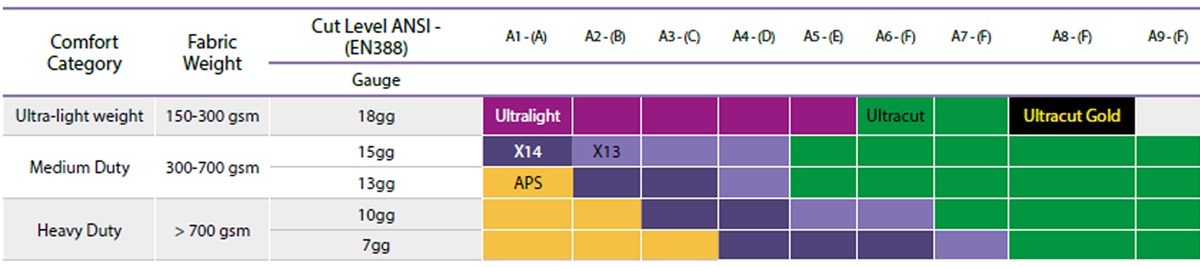

Coats Armoren: Complete Product Range

Ultralight & Ultracut: fastest growing sectors in Hand Safety and require innovative engineered yarns.

How to decide which Coats Armoren product to use for what application?

| The gold standard of cut protection. Extreme high cut for fine gauge knitting. | ||

| For ultimate dexterity and laser-fine protection in 18 gg ultralight-weight gloves | ||

| The power of extreme cut protection. High cut A5-A9 in medium duty gloves. | ||

| Best suited to replace spun para-aramid or para-steel in medium duty gloves | ||

| Great value to replace HPPE or HPPE Glass in medium duty gloves | ||

| General purpose yarns made with spun para-aramid and HPPE fibres |

Note: Please refer to separate product sheets of each sub-brand of Armoren family in order to get detailed specifications of each engineered yarn. Each sub-brand uses uniquely special yarn spinning techniques and different combination of fibres and new generation materials. Selection of type of core, metal micron, wrap blend content %, etc will depend on the specific functional needs of the type of glove being designed. Multiple counts and ply constructions are available within each sub-brand to meet the needs of the full range of gauge-cut resistance product quadrants. Use Armoren Protect+ for anti-microbial and Armoren Orbit for vortex spun applications.

Coats Armoren: Multi-risk protection

Coats is a global innovation leader pioneering the textile industry. It has developed disruptive technology platforms like J Spun that meets safety industry’s challenges. It has invested in advanced research of next generation materials. Its Innovation Hubs can design special fibre / yarn blends and fabric solutions that provide Multi-Risk Protection and other functional attributes on as-needed basis to meet emerging and future industry needs:

Features and Benefits

- Electric arc flash resistance to meet F2675M-13 HRC level 2 (8 cal/cm2), HRC Level 3 (25 cal/cm2) and above

- High contact heat properties at 350°C EN 407 Level 3

- Anti-microbial and anti-bacterial protection under Armoren Protect+ brand

- Molten Metal Splash hazard protection

- Hypodermic needle resistance under ANSI 105 (150 Newtons)

- High mechanical impact ANSI ISEA 138

- Electrostatic (EN 1151/ANSI 16350), silicone- free, modular clean room ambience

- FDA food handling requirements 2002/72 EC

- Chemical exposure; Oekotex, ReacH certifications