Do your filters "take the cake" or release it?

Expertise and Innovation - Stories by Coats

Grocery shopping is an activity millions around the globe partake in daily. When shopping for your daily or weekly supply of food, filtration is not likely at the top of mind. However, in the food and beverage industry it is one of the most critical processes to ensure health and safety standards are being met. Globalization of this industry has continued to blur the geographical boundaries of standards and processes.

Food and beverage production is one of the most important industries in the world, and also has some of the most stringent regulations globally. Proper filtration in the production process is key to assuring consumers’ health and safety is not put as risk.

There are two types of filtration involved in the food and beverage industry. Dry filtration and Wet or Liquid filtration. Both are key to the production of food and beverages, however liquid filtration continues to dominate the market. The growth of certain industries, including food and beverage, is expected to increase the demand for filtration that supports the liquid filtration market. According to several reports, liquid filtration is estimated to account for 76% of the market share from 2016-2021, growing at much higher rate than dry filtration.

(http://www.marketsandmarkets.com/PressReleases/industrial-filtration.asp)

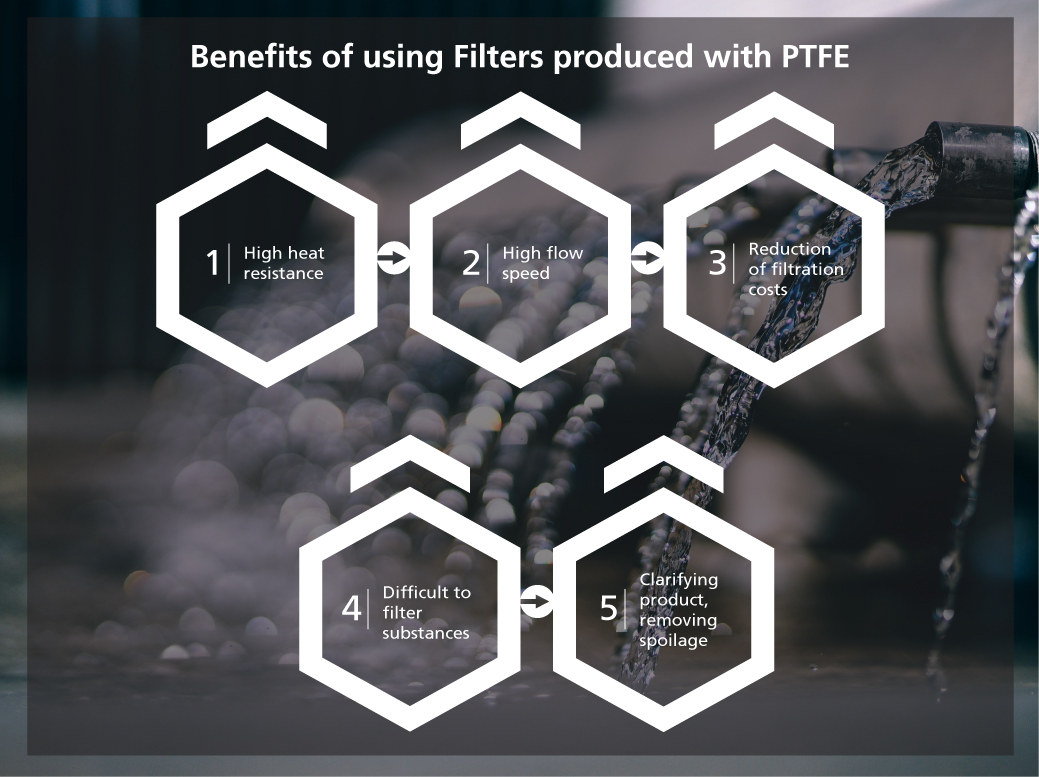

Filtration in the production of liquids is a critical component with it comes to extending shelf life and preserving flavor. The filtration process has several stages, the most important being particulate removal. Any substance that could cause problems later in the process must be removed in the very early stages. Filters with seams made of PTFE (Polytetrafluoroethylene) allow for the greatest opportunity to capture the "cake" and allow for easy release when it comes to the cleaning process, allowing only the good stuff to filter through.

An industry leading the charge in filtration needs is the brewing industry. This market is forecasted to grow at a compound annual growth rate (GAGR) of 5% from 2016 to 2022, with a project value of 3.01B (USD). This is being driven by continued growth globally. (http://www.marketsandmarkets.com/food-and-beverages-market-research-6.html)

In the brewing process, the wort (malt-sugar solution that is boiled prior to fermentation) is separated from the mash (hot water steeping process that promotes enzymatic breakdown of the grist into soluble, fermentable sugars). This part of the brewing process requires stringent filtration, with high flow rates and needs good cake release. This process is done under high heat, which can cause "cake" to get caught up in filters and potentially cause unwanted particles and bacteria to seep through. The use of filters made with PTFE allow for "cake" release, thus only allowing the final product through, free from any unwanted particulates.

Coats Glasmo Tee has been developed for the manufacture of demanding filtration applications. It is a temperature resistance fiber glass sewing thread with exceptional thermal stability with up to operating temperatures of 593ºC. The excellent "cake release" filtration properties are on account of the unique PTFE technology. Learn more about how versatile Glasmo Tee is in demanding filtration applications.